Project Introduction

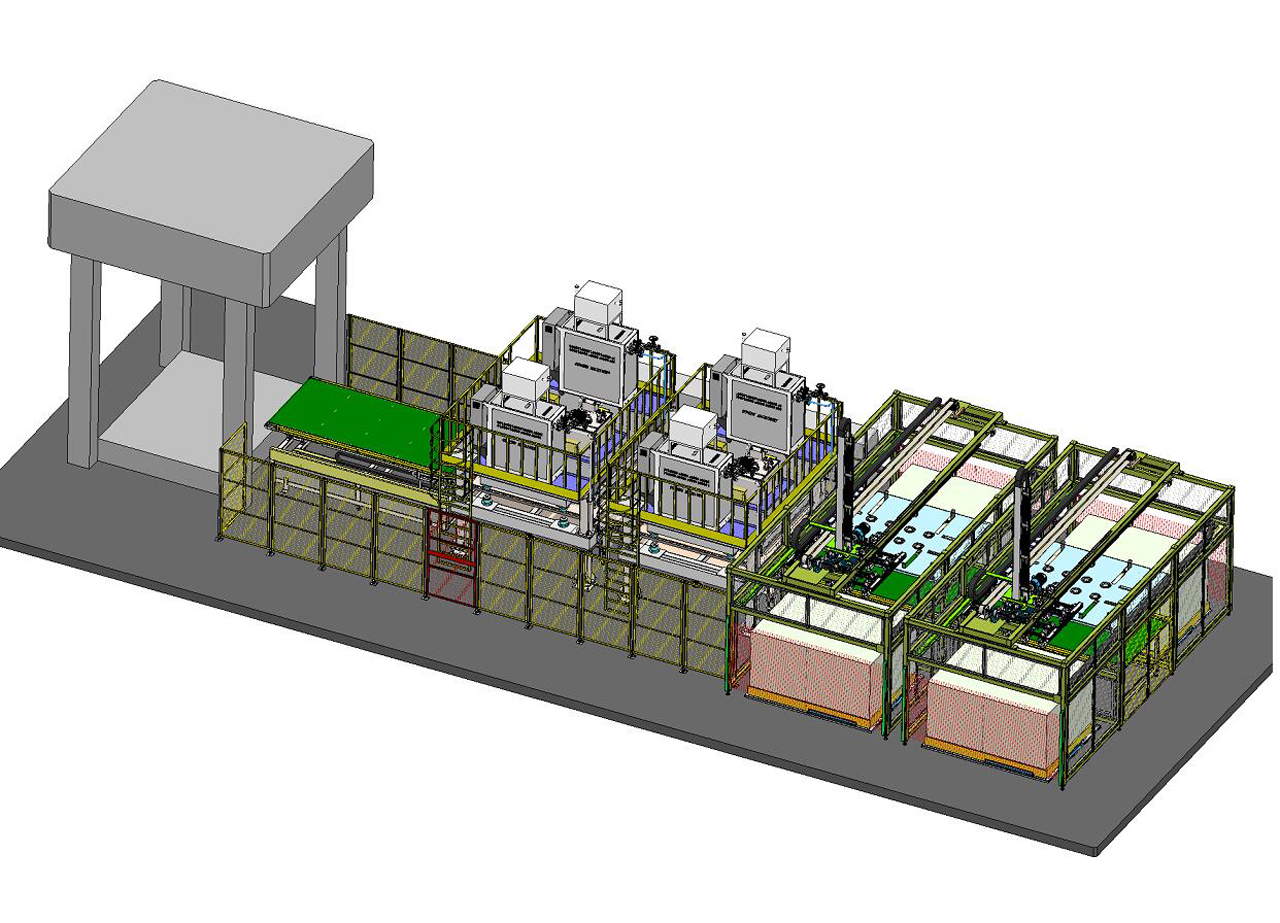

The car carpet heating and forming production line consists of a feeding platform (feeding section), an oil temperature machine heating (heating section), a forming press (forming section), an automatic unloading device (lower part section), a conveying and clamping system, and other auxiliary devices.

The heating section is heated by an oil temperature machine with PID temperature control, providing stable, accurate, and adjustable heating temperature. The heating time can be set according to process requirements, and the heating plate can be adjusted according to the material width.

Project Introduction;

1. This production line specializes in providing interior manufacturers with molding equipment for producing automotive interior parts (such as car roofs, insulation pads, carpets, coat racks, trunk covers, car wheel covers, etc.), with high precision, energy saving, and high degree of automation.

2. Using an oil temperature machine for heating, it can provide stable and accurate temperature to the interior mold during the production of interior parts, ensuring the stability of each batch of products in terms of elasticity, color, and quality.

3. This series of products has a high degree of automation, using robots for automatic loading and unloading, PLC programmable control, and the ability to individually control individual heating systems of the equipment.

Process parameters: Platform heating temperature: 180~300 ℃; Partial loading; Molded products; Contact heating.